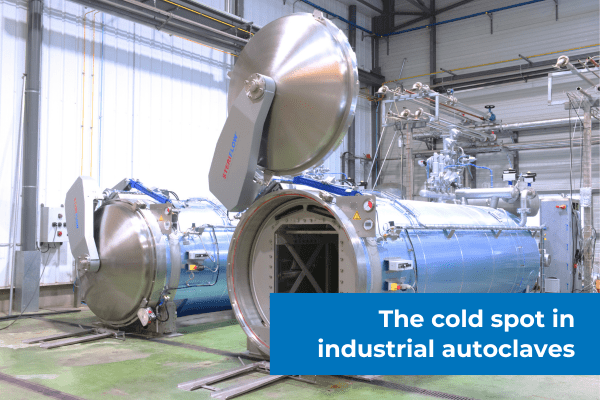

The cold spot in industrial autoclaves

Industrial autoclaves are essential equipment in the food industry, enabling thermal processing of numerous products. However, mastering sterilization or pasteurization in these industrial devices requires identifying the “cold spot”.

Determining the location of the cold spot is crucial to ensure food safety and optimize production processes.

What is the cold spot in an autoclave?

The cold spot is defined as the area of the autoclave where products receive the least heat. It’s often the place where the temperature reaches the sterilization or pasteurization setpoint most slowly. Consequently, it’s the critical point for ensuring the microbiological safety of processed products.

Factors influencing the location of the cold spot

Several parameters can affect the position of the cold spot in an autoclave:

- Autoclave configuration: the design of the device, particularly the location of steam and compressed air inlets

- Heating method: autoclaves using water cascade, spray, or air/steam mixture have different thermal dynamics

- Loading plan: the arrangement of products in the autoclave influences the circulation of heating fluids

- Nature of products: size, shape, and physical properties of containers affect heat distribution

- Ventilation system: in some autoclaves, a fan is used to circulate air in the chamber, and this forced circulation impacts thermal homogeneity.

The cold spot, critical point of thermal treatment

Insufficient thermal treatment at the cold spot can have serious consequences, such as:

- Health risks with potential survival of pathogenic or spoilage microorganisms

- Economic losses with probabilities of product recalls or destruction of non-compliant batches

- Damage to brand image with loss of consumer’s and distributor’s trust (in case of recall).

How to identify the cold spot?

Thermal mapping

Thermal mapping

Conducting a detailed thermal mapping of the autoclave is an essential step. This operation involves placing temperature probes at different points in the chamber and load to measure temperature evolution during a complete cycle. This mapping allows:

- Precise localization of the cold spot

- Evaluation of temperature differences within the autoclave

- Identification of potential “colder” zones

It is recommended to perform this mapping regularly and after any significant modification of equipment, utilities, or loading plan.

How to mitigate the cold spot?

Loading optimization

Loading optimization

The loading plan should be designed to promote optimal circulation of heating fluids. It’s necessary to:

- Space products sufficiently to allow steam or water circulation

- Use appropriate racks, spacers, and accessories to improve heat distribution

- Avoid overload areas that could obstruct steam passage or create “umbrella effects”

Improvement of forced circulation

Improvement of forced circulation

Installing or optimizing a mixing system can significantly reduce temperature differences:

- Circulation fans adapted to the autoclave geometry

- Deflectors to direct air and steam flows.

Adjustment of operating parameters

Adjustment of operating parameters

Based on mapping results, it is possible to optimize cycle parameters by:

- Adjusting steam and compressed air flow rates

- Adjusting water quantity and flow rate

- Modifying temperature ramp-up phases

- Optimizing purge and mixing phases

Staff training and awareness

Staff training and awareness

Operators’ understanding of the cold spot importance is essential. Therefore, it is necessary to train staff on good loading practices and raise awareness about risks related to insufficient thermal treatment. Reporting of observed anomalies is also crucial.

Continuous monitoring

Continuous monitoring

Mastering the cold spot requires regular monitoring by:

- Routinely performing mappings or in view of an anomaly

- Rigorously validating sterilization or pasteurization schedules

- Conducting heat penetration tests on products treated at the cold spot

Mastering the cold spot is a major challenge for any industrialist using autoclaves for thermal treatment. Steriflow superheated water cascade autoclaves guarantee very fine temperature homogeneity, considerably reducing the risk of cold spots.

learn more: mapping and training services