Autoclave for food sterilization

For the last 40 years, STERIFLOW SAS – located in France – has brought solutions to the food industry with regard to pasteurization, sterilization and vacuum cooking, with a view to meeting requirements from professionals in the food business.

Our range of autoclaves for food sterilization

Steriflow offers a wide range of autoclaves for professionals in the agri-food business, with diameters set between 900 mm and 2,300 mm, their capacity ranging from 1 to 12 baskets. Standard models with options for adapting to special requests within the food industry. Come and discover our various models, such as the Steriflow Static, our company’s flagship and iconic model (for can, pouch, jar, glass, plastic bags, etc.). It is easy to use and limits energy consumption thanks to the recovered steam condensates. The Shaka is an autoclave launched in 2009, and is a novel industrial product which, thanks to a shaking process, ensures much better preservation of the food’s natural texture. Our technical department is available should you need any help making a decision fitted to your needs.

Our food autoclaves operate thanks to the water cascading process.

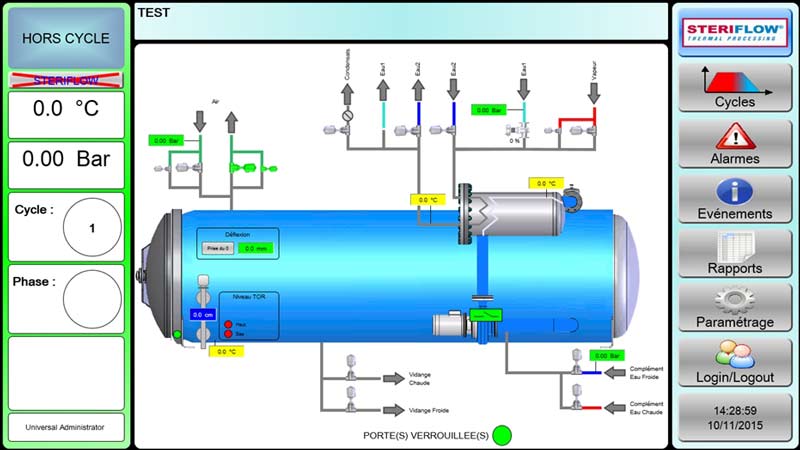

Each cycle is completed automatically, according to the settings memorized in the programmer fitted with an MPI Expert. The filled baskets are manually introduced into the STERIFLOW®. The door is closed manually and locked mechanically thanks to a pressure cylinder. After having possibly added water up to the ballast level (or filled during the first cycle), the pump is activated. The process water cascades onto the products to be treated, at high flow rate. The hydraulic circuit in the STERIFLOW process is as follows: pump – Platular® exchanger – cascading manifold – onto the products – filtering – pump, etc. Throughout the cycle, the counter-pressure is controlled by injecting or bleeding compressed air inside the vessel, using two automatic valves. Then the pump stops. A light signal indicates the end of the cycle, meaning the door can be opened. The STERIFLOW is then unloaded and ready for a new cycle.

- The heat exchanger:

It is manufactured by the company Barriquand Échangeurs near our site in Roanne. They have come up with a specific system, perfectly adapted to the Stériflow process. We are therefore the only ones with this exchanger design, entitled the “platular®“. It provides more solidity, and its maintenance requirements are reduced compared to other standard types of exchangers. There are no joints between the exchanger plates: they are welded to one another. This formula, offered as a base feature, reduces the cost of spare parts and is thus more economical. Yet another of Steriflow’s technical innovations! Furthermore, the lack of joints is an environmental asset, as less material is used during manufacture.

- Programming the counter-pressure cycle:

To prevent the packaging from deforming, compressed air is injected into the autoclave: this is known as counter-pressure. It is programmed according to the type of packaging used (cans, glass, jars, etc.) and to the filling settings already defined. It does not depend on the programmed temperature.

- Energy savings:

The water is heated in the exchanger; it does not enter the autoclave. The steam’s condensates are recovered from the exchanger, making our industrial sterilizer much less energy-consuming than its competitors’.

- Power:

Fitted with a powerful pump, for shorter and more homogeneous cycles. All the products inside the autoclave get the same thermal treatment, regardless of their position, thus enabling optimal food sterilization. The reduced cycle time also ensures better results.

- The door:

It locks thanks to a pneumatic system, blocking it throughout the entire cycle. The design is the same regardless of whether the opening is horizontal or vertical.

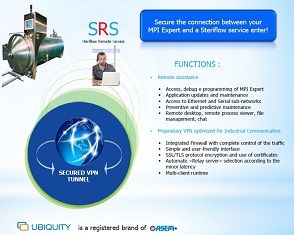

- MPI Expert:

A high-performance control system that is very easy to use and through which the sterilization or pasteurization settings are automatically saved. A comprehensive solution that includes operation, data saving and digital summaries.