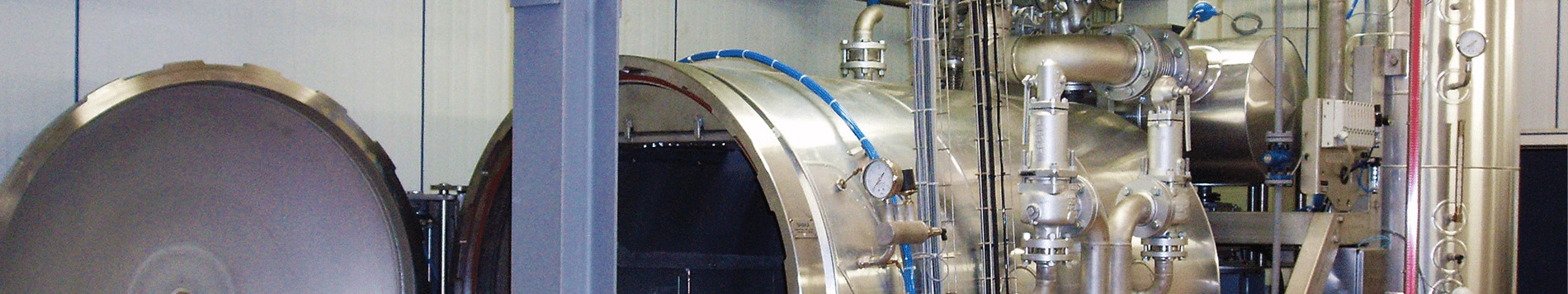

Industrial autoclave for cans, jars, trays and much more

Steriflow autoclaves are highly versatile and flexible to use.

Choosing a Steriflow industrial autoclave means giving yourself the opportunity to upgrade your range of products and packaging without having to change equipment. Our industrial sterilizers and their accessories (baskets, racks…) can be adapted to any type of container, Glass jars or metal cans, pouches, trays and cups (plastic or aluminium), cups (plastic or aluminium)… The Steriflow superheated water cascading sterilization process ensures that the appearance of the packaging and tightness are preserved thanks to the perfect control of the back pressure independent of temperature and guarantee food preservation and microbiological quality.

Steriflow sterilization autoclaves offer great flexibility and ease of use.

Choosing a Steriflow industrial autoclave means being able to expand your range of products and packaging without having to change equipment.

Our industrial autoclaves and their accessories (baskets, racks, etc.) can be adapted to all types of containers:

- glass or plastic jars

- metal cans

- pouches,

- plastic or aluminum trays and cups

- glass or plastic pots

- etc.

The Steriflow superheated water trickling sterilization process guarantees:

- preservation of packaging appearance,

- water-tightness, thanks to perfect temperature-independent back-pressure control,

- food preservation and microbiological quality.

Can sterilization by autoclave

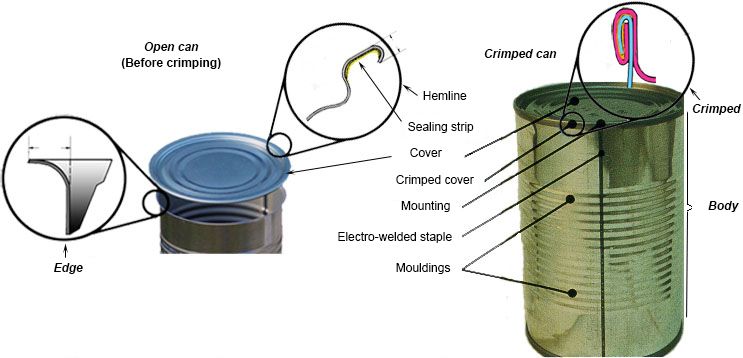

Since 1795, tin cans have been astonishingly robust and timeless. It is still used today by food industry professionals, and is recognizable by its famous moldings. Originally made of tinplate, technological discoveries led to the development of tin-free steel, and later aluminum and multilayer.

What are its main qualities ?

What are its main qualities ?

- Sturdiness: it withstands shocks without problem,

- Hermeticity: a real barrier to microbes.

- Shelf life: the product can be kept for several years.

Propose the best sterilization solution for cans and jars

In the Steriflow test laboratory, several pilot autoclaves are available to customers to allow them to compare the different processes offered, and choose the one that will best suit their product or packaging.

In addition, in order to offer the customer the best suited to his production constraints solution, and to define the number of sterilizers required to meet the desired rate, Steriflow’s team assess capacity based on three elements: the rate of the upstream process, the dimensions / types of packaging, and the heat treatment cycle time.

Sterilization of jars and cans – the principle

Sterilization of jars and cans – the principle

At room temperature, bacteria growth is maximum. To avoid excessive waiting times that could lead to the proliferation of microorganisms in the packaged product, the manufacturer has a limited time to start the sterilization process.

Loaded automatically or manually, the baskets are inserted into the autoclaves. Once the door is closed, the sterilization cycle starts. For all bacteria present to be destroyed and the product properly sterilized, the treatment temperature must be above 100°C (average temperature observed for a sterilization cycle: 120°c).

The sterilizing value or FO to be achieved is defined by the manufacturer and will depend on the initial contamination of the product and its bacteriological characteristics.

To reduce cycle time, some manufacturers increase the temperature of the sterilization bearing, or opt for industrial shaking sterilization systems (Rotary, Shaka). Shaking the product during the sterilization cycle increases the rate of heat penetration.

Once the sterilization stage is complete, the cans are cooled quickly by water runoff. During this phase in particular, the control of the back pressure independent of the temperature characteristic of the Sterflow process is essential. This prevents leaks on glass jars or deformation of cans.

At the end of the cycle, the baskets are taken out of the autoclave. Canned food or jars are labelled, packaged and stored ready for sales.

Specific cases: sterilization of bags or trays

Temperature-independent counterpressure control is a major advantage of Steriflow’s industrial water cascading sterilization process. This process is ideal for the heat treatment of flexible and semi-rigid packaging, allowing their integrity to be perfectly preserved.

During the sterilization process, the packaging will be subjected to thermal and pressure constraints. Under the influence of heat, the content of the package expand. As the internal pressure (in the product) increases with temperature, it is essential to counter square this pressure to avoid damaging the aesthetic appearance of the packaging (irreversible deformation) and breaking the seal. If the pressure in the autoclave is lower than the pressure in the packaging (case 1), the latter may explode. Conversely (case 2), if the pressure in the industrial sterilizer is higher than the pressure in the packaging, an implosion of the product is possible. For each situation it is essential to finely control the pressure in the chamber, independently of the temperature, which is perfectly possible with a Steriflow autoclave with water cascading process.

Discover our autoclaves for the sterilization of food products