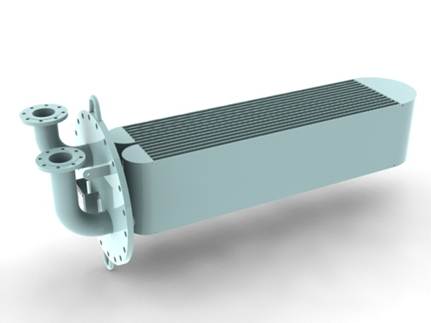

Platular® heat exchanger : Energy savings and less maintenance

How does it work ?

The Platular® heat exchanger used by Steriflow autoclave was patented in 1974 by Barriquand Echangeur Company. It is a specific system perfectly suited to the super-heated water cascading process of Steriflow. It is well adapted to successive heat and cool cycles and to pressure differentials. They are manufactured on site at Roanne, France.

The operating principle of the Platular® heat exchanger is based on the separation of the internal process water circuit and the external steam and cooling water circuits. This process has the greatest energy savings thanks to the full condensate recovery. Moreover, this system gives you the possibility to use external water of various qualities and sources for the cooling, for instance river water.

This exchanger is manufactured to be very strong in order to minimize your maintenance costs. Its welded plates are made in stainless steel 316 L, the most resistant material against corrosion. As a consequence, this exchanger has an average lifetime of 20 years, and some of our customers keep it for more than 25 years. In addition, the Platular® Exchanger doesn’t have any gaskets, leading directly to less maintenance.